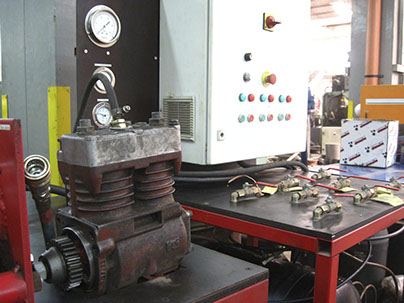

The first Air Brake Valve and Re-manufacturing Centre in East and Central Africa was commissioned by Pipe Manufacturers Ltd in April 1999. A wide range of valves and air compressors are reconditioned and offered as exchange units to consumers at a fraction of the cost of new units. All valves and compressors are fully tested on purpose built benches by highly skilled personnel. Most major brands are catered for and new units are also stocked for sale.

With the addition of new service bays, test equipment we now have a capacity of servicing 1200 Valves and 100 Compressors every month.

Electronic Control Modules are incorporated into various different air valves on trucks. We are currently undergoing training for the repair and service of these valves.

.jpg?crc=4146637565)

Air Dryers

Hand Valves

Solenoid Valves

Relay Valves

Quick Release Valves

Pressure Limiting Valves

Power Steering Pumps

Multi Circuit Protection Valves

Foot Valves

Distribution Valves

Clutch Servos

Load Sensing Valves

Charging Valves

Brake Chambers

Compressors

Compressed Air Brake System

Compressed air brake systems are typically used on heavy trucks and buses (Note the difference between pneumatic brakes and pneumatic/hydraulic). The system consists of service brakes, parking brakes, a control pedal, an engine-driven air compressor and a compressed air storage tank. For the parking brake, there is a disc or drum brake arrangement which is designed to be held in the 'applied' position by spring pressure. Air pressure must be produced to release these "spring brake" parking brakes. For the service brakes (the ones used while driving for slowing or stopping) to be applied, the brake pedal is pushed, routing the air under pressure (approx 100-125psi) to the brake chamber, causing the brake to reduce wheel rotation speed. Most types of truck air brakes are drum units, though there is an increasing trend towards the use of disc brakes in this application. The air compressor air draws filtered air from the atmosphere and forces it into high-pressure reservoirs at around 120 PSI. Most heavy vehicles have a gauge within the driver's view, indicating the availability of air pressure for safe vehicle operation, often including warning tones or lights. Setting of the parking/emergency brake releases the pressurized air pressure in the lines between the compressed air storage tank and the brakes, thus actuating the (spring brake) parking braking hardware. An air pressure failure at any point would apply full spring brake pressure immediately.

+254 702 655368

+254 702 655482

+254 702 651143

+254 702 651127

+254 702 650092

+254 706 062633

+254 736 557755

+254 738 775577

+254 739 774477

+254 733 615328

+254 739 393939

sales@pipeman.com